The STELDA 4S Promise

Strength

Security

Sustainability

Saving

Our Range of Automated Packaging Solutions

STELDA

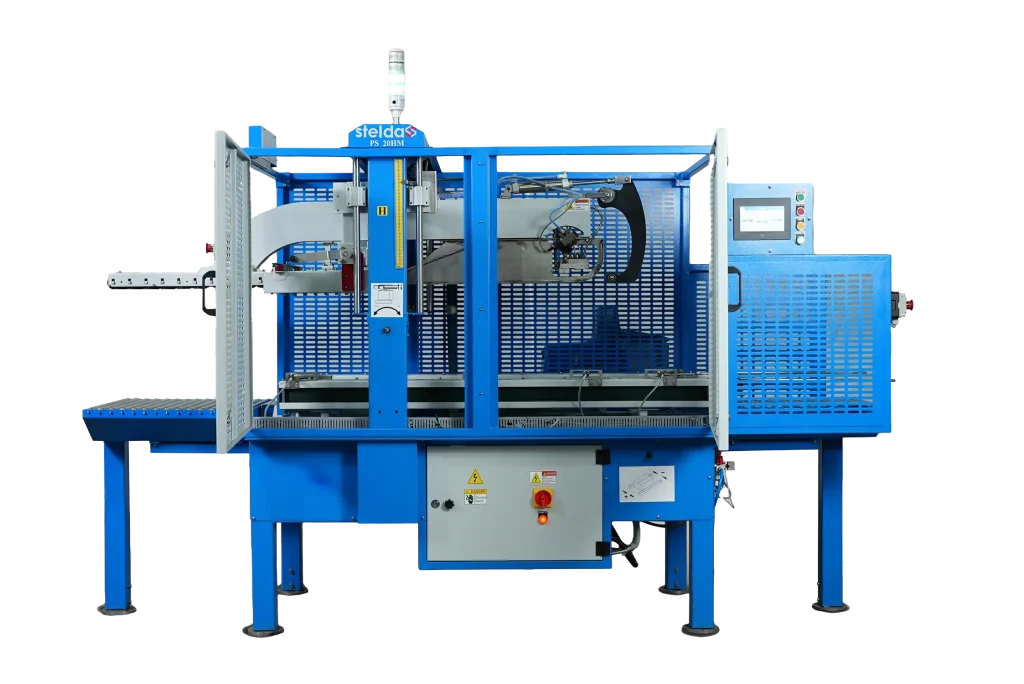

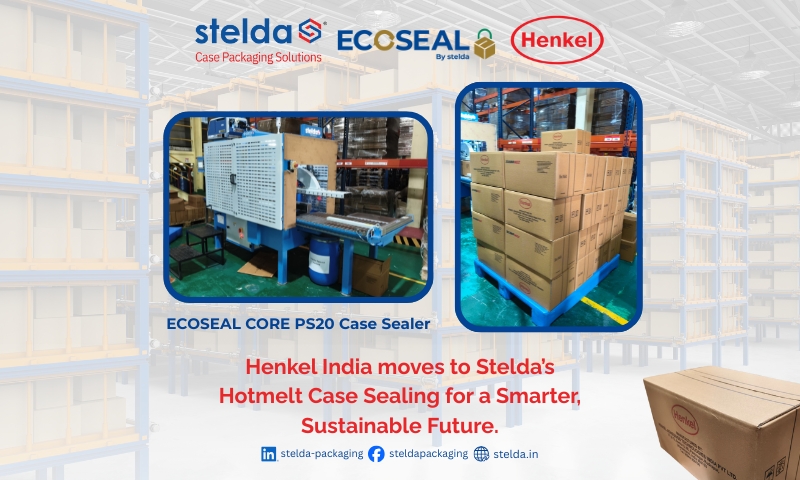

STELDA PS 20 HM series

The STELDA PS 20 HM series delivers trusted packaging solutions with preset or batch production case sealers. These machines offer best-in-class options for box sizes, speed, or type of sealing. The tamper-evident sealing protects against transit damages while also ensuring enhanced efficiency and reliability in industrial packaging solutions.

STELDA PS 20 HM series

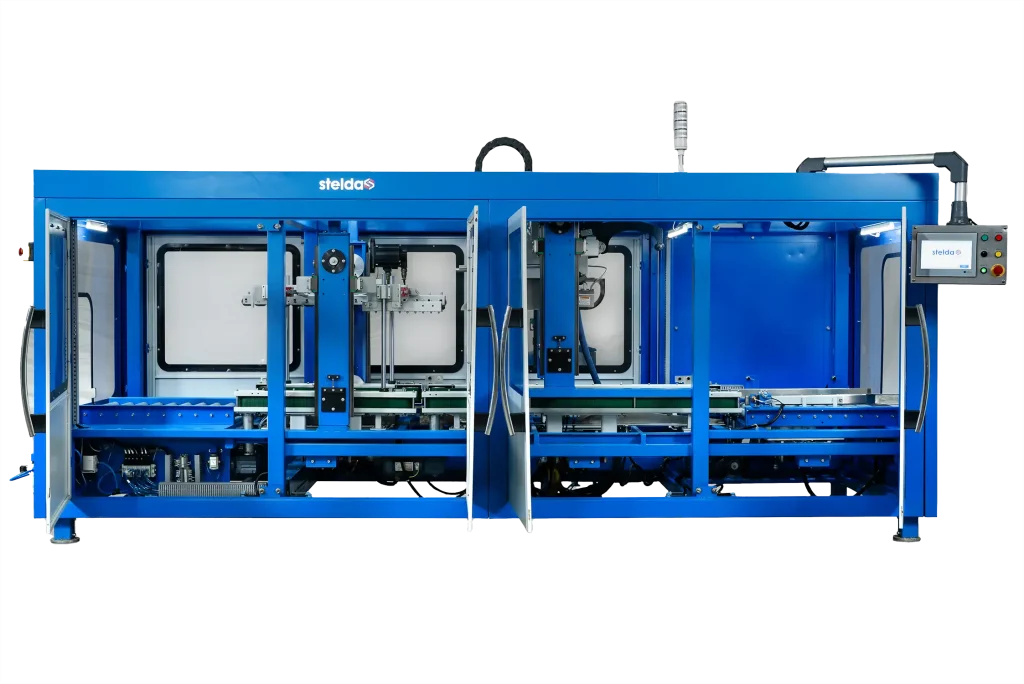

STELDA AR 500 GT series

The STELDA AR 500 GT is a state-of-the-art carton sealing machine based on patented technology. This fully automated system can handle any random-sized box, setting it automatically via QR Code or physical dimensions. Designed for advanced packaging automation, it ensures seamless operations and unmatched precision.

STELDA AR 500 GT series

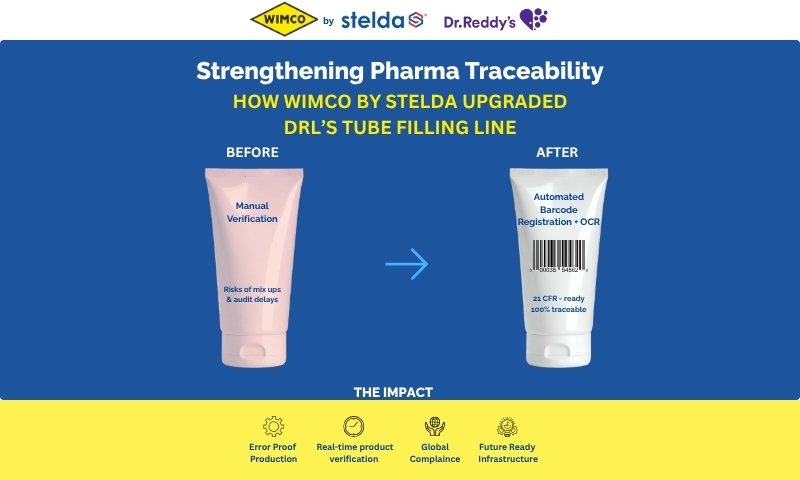

WIMCO

WIMCO GAN 120

The WIMCO GAN 120 is a high-speed tube filling machine built for precision and efficiency. Designed for diverse industrial needs, it supports various tube sizes and materials, ensuring robust, reliable, and consistent performance for global brands.

WIMCO GAN 120

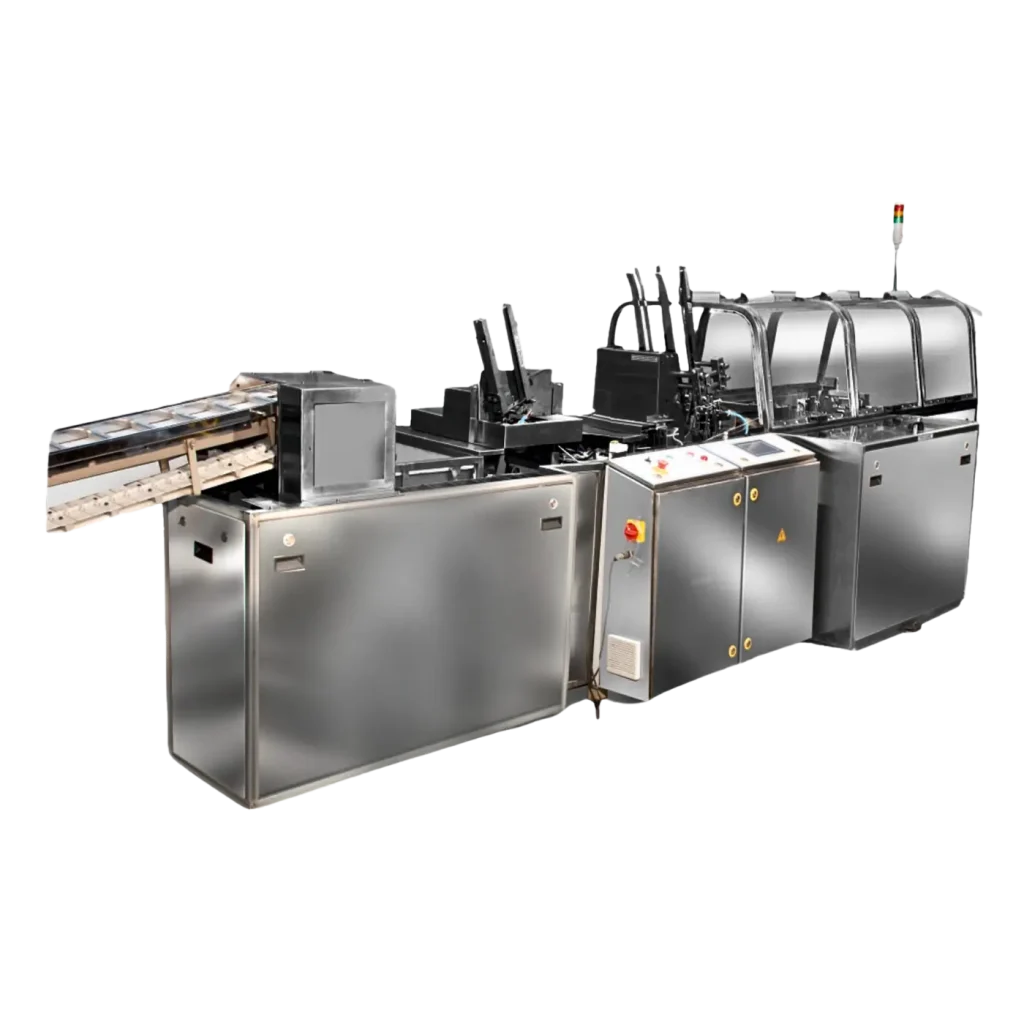

WIMCO PAC 120

The WIMCO PAC 120 is an advanced carton sealing machine that combines automation with superior operational safety. Featuring smart capabilities, it offers high-performance packaging solutions to optimize production lines while reducing transit damages.

WIMCO PAC 120

Key Metrics

Years of

Expertise

Clients

Served

Service

Engineers

Machine Installations

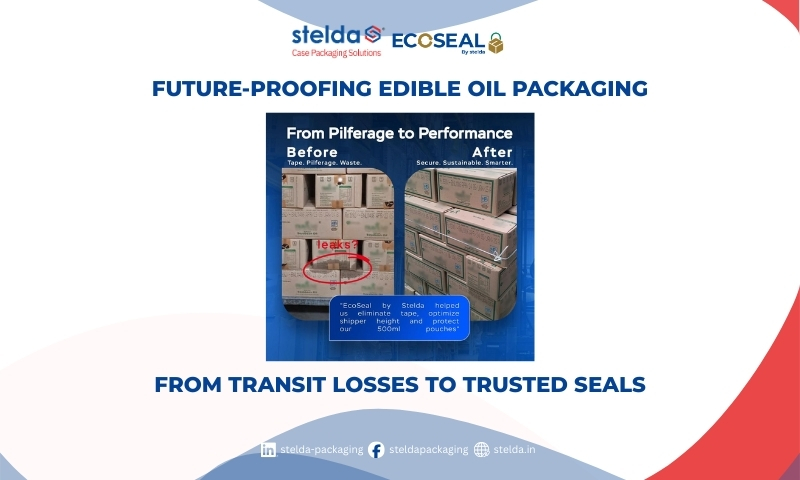

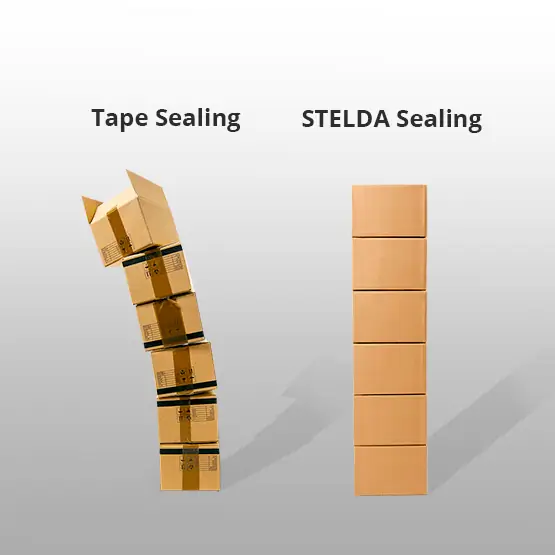

Reduce Product Damage

Increase your shipper cartons’ resistance to loads in storage and transit with our trusted packaging solutions that prevent spoilage and pilferage.

Eliminate Single-Use Plastic

No more tapes, straps, stretch films, or shrink wraps. Reduce your carbon footprint with our sustainable industrial packaging systems.

Handle Stock with Ease

No more tapes, straps, stretch films, or shrink wraps. Reduce your carbon footprint with our sustainable industrial packaging systems.

Safety-First Approach

Our high-performance packaging machines prioritize operational safety

Stelda's Spotlight

Monitor live information such as SKU details, glue and energy consumption levels, and generate real-time case-sealing reports. Accessible remotely, these features ensure quick decision-making through advanced packaging automation

Monitor live information such as SKU details, glue and energy consumption levels, and generate real-time case-sealing reports. Accessible remotely, these features ensure quick decision-making through advanced packaging automation

Industries that we serve

FMCG

Pharma

E-Commerce & Logistics

Automotive & Industrial Goods

Cosmetics