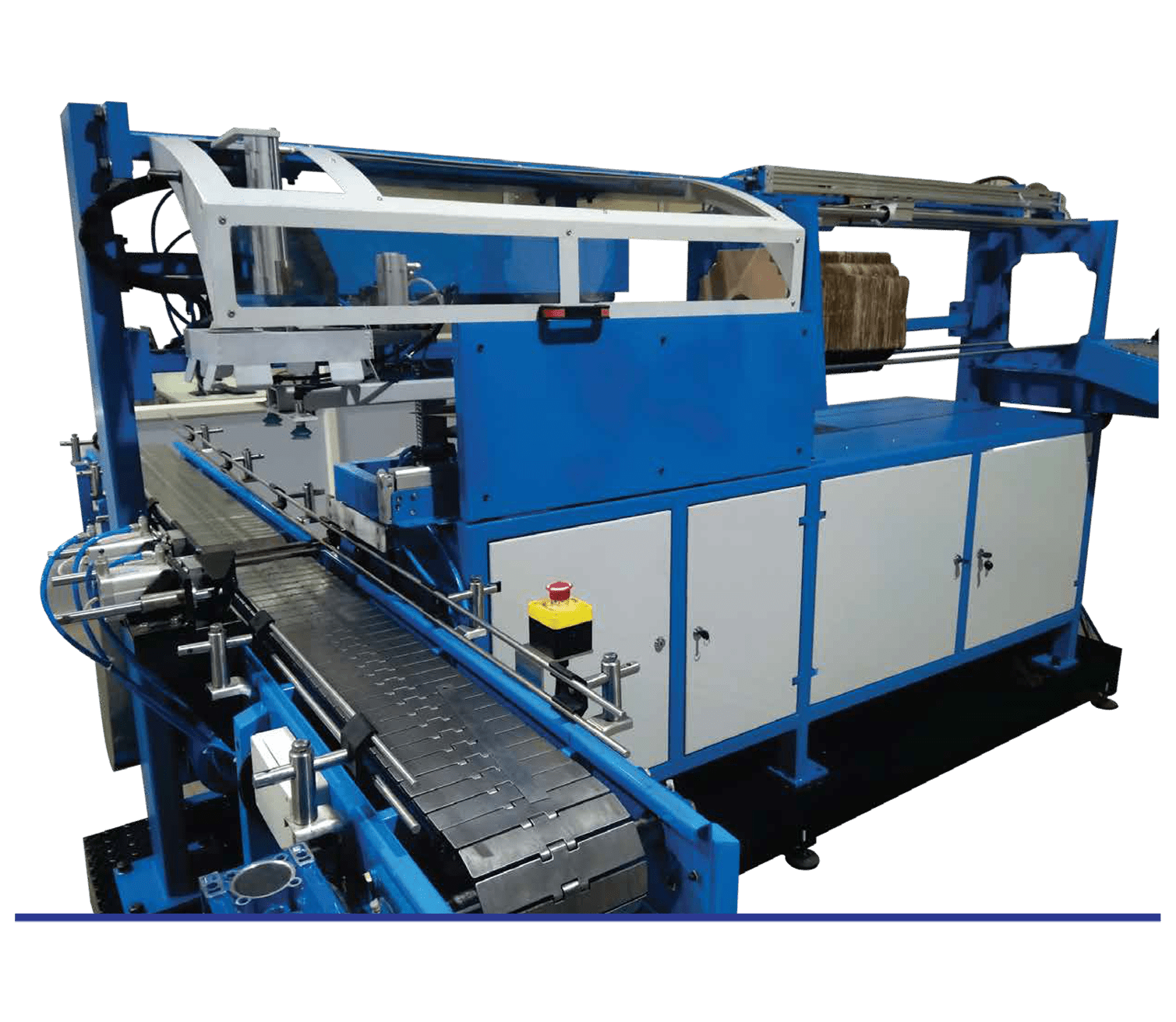

STELDA TCP15

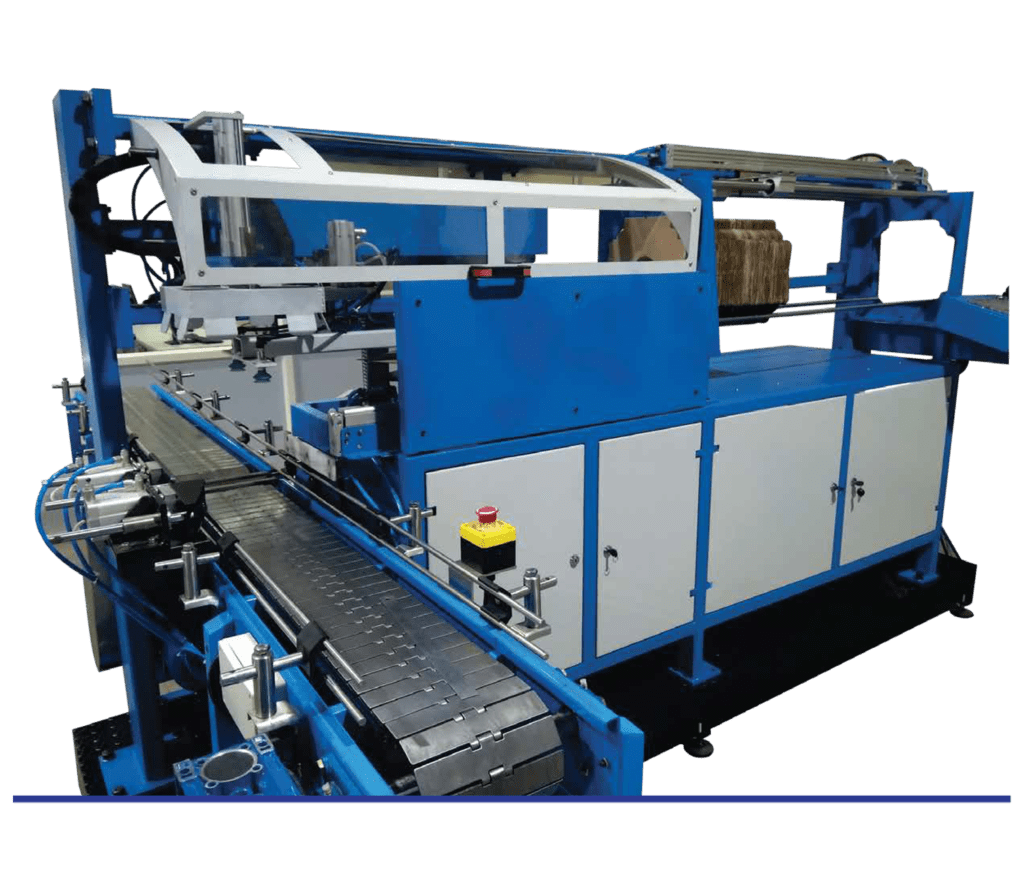

Stelda Automatic TCP 15 picks up corrugated from a stack applies hot melts adhesive and places it in top of a 15 Liter / 15kg tin containing edible oil. The machine is connected completely in line with oil filling plant, and the collar fixing operation is done at speeds synchronizing with the line speed.

FEATURES

- Non-stop feeding of collars

- Servo operated dual arm pick and place

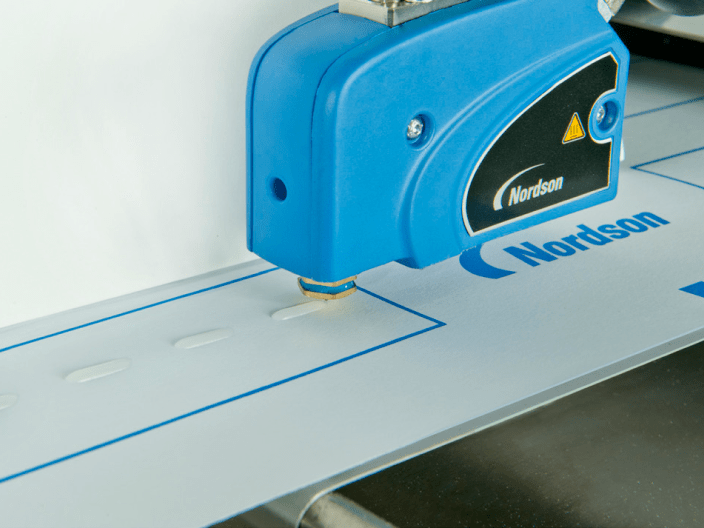

- Nordson® gluing system as standard

- Glue saving

- Collar feeding

- Collar tiltingt

- Collar pick and place

- Collar rotation for precision gluing

- Linear nozzle movement in sync with collar rotation

- Collar pressing

- Dual conveyor system

- Optional layouts based on requirement

- Human safety features

- Real Time Monitoring

The machine has following sections each of them programmed to execute the required sequence.

- Collar feeder (De-stacker)

- Collar tilter (Tilts the collar from vertical to horizontal)

- Pressing station

- Pick and place (Moves the horizontal collar, to Gluing station, and after gluing to the Tin Top)

- Gluing station (Nordson system, Rotating table, Linear motion of dispenser synchronized with rotation)

TIN SIZE

| Size of the Tin | 240mm x 240mm x 320mm (LxWxH) |

SPECIFICATIONS

| Model | TCP15 |

|---|---|

| Maximum Filled Tin Weight | 16 kg |

| Working Speed | 15 tins/ minute |

| Oil Tin Size in mm L X W X H | 240 x 240 x 320 |

| Sealing Method | Hot Melt Glue |

| Electrical Requirement | 3 Phase, 440V, 50 Hz, 7 kW |

| Air Pressure Requirement | 15 CFM, 6 Bar (Dry Air) |

| Mechanical Speed | 15 tins per minute |

| Gluing System | Nordson System |

Machine Standards

Our machines are CE compliant & ISO:9001 certified. STELDA packaging systems come with Nordson® Industrial Gluing Nozzles controlled by SMART CONTROL SYSTEMS for on-demand gluing using temperature controlled adhesives to maintain adhesion consistency.

Oil tins collar sealed the STELDA way using precision gluing are more sustainable than those with collars strapped manually. Precision glued collars leave clean fibre tear, producing instant tamper evidence.

Other Machines

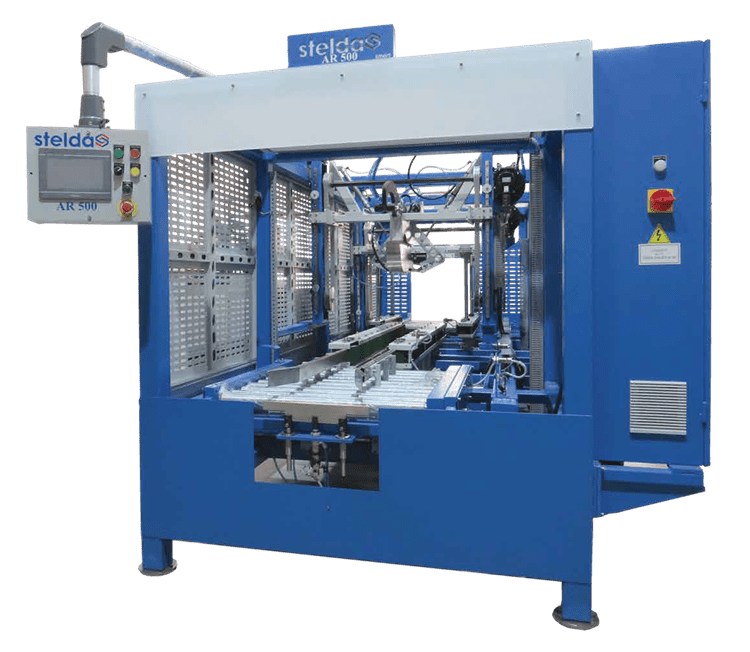

STELDA AR500

STELDA AR500 is a state of the art, fully automated case sealing machine based on a patented technology that can accept any random sized box. The machine is set for the box either by reading QR code ...

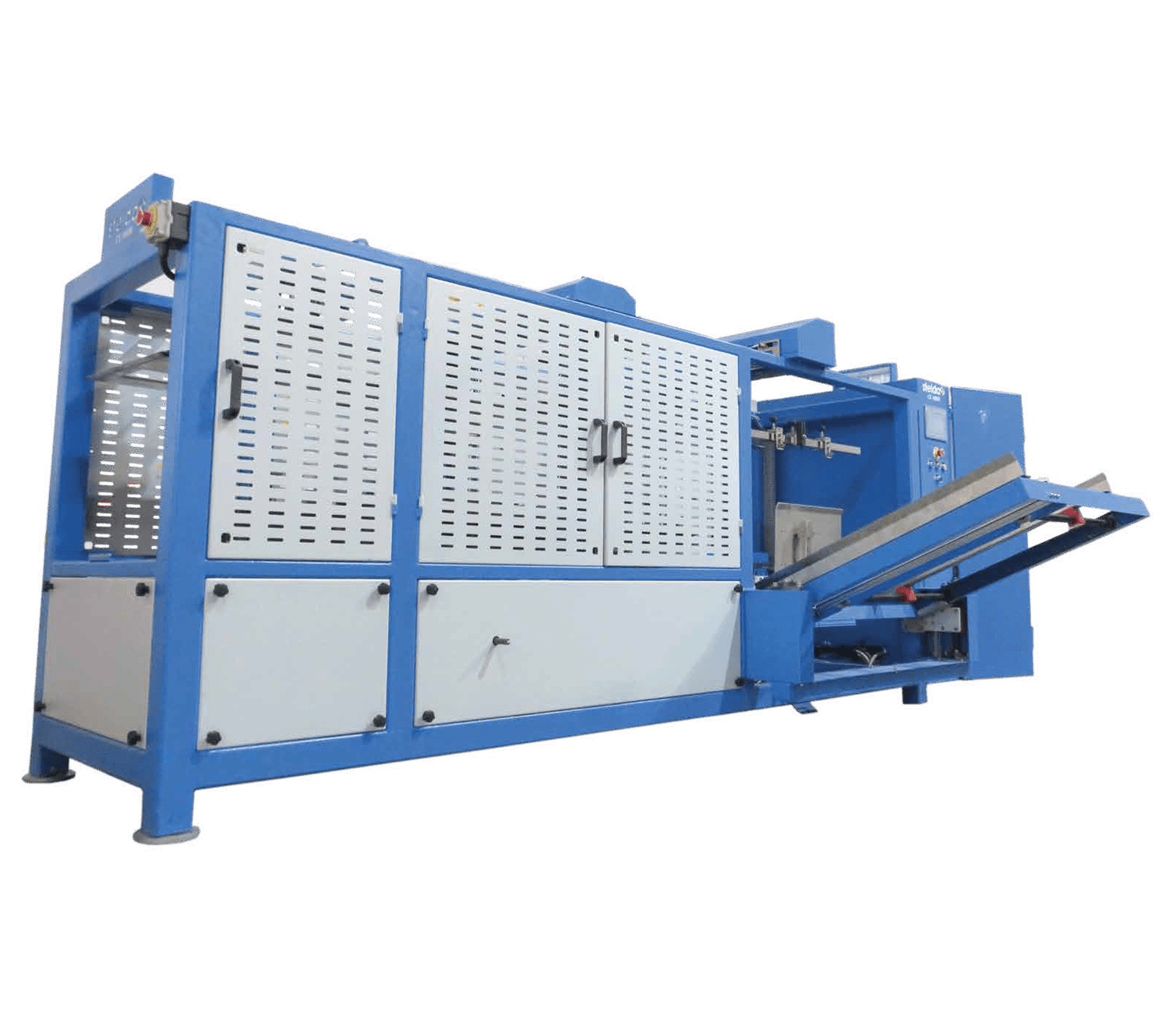

STELDA CE10

Stelda CE 10 is an automatic Case Former / Erector with PLC controls. Quick job change-over is effected through touch screen controls, using servo drives.Vertically stacked ...

STELDA PS 500

Stelda PS 500 series preset or batch production case sealers have the best in class options of box sizes, speed or type of sealing. The tamper evident case sealing provides protection...